Fixed and portable industrial tent structures: how to choose the best one?

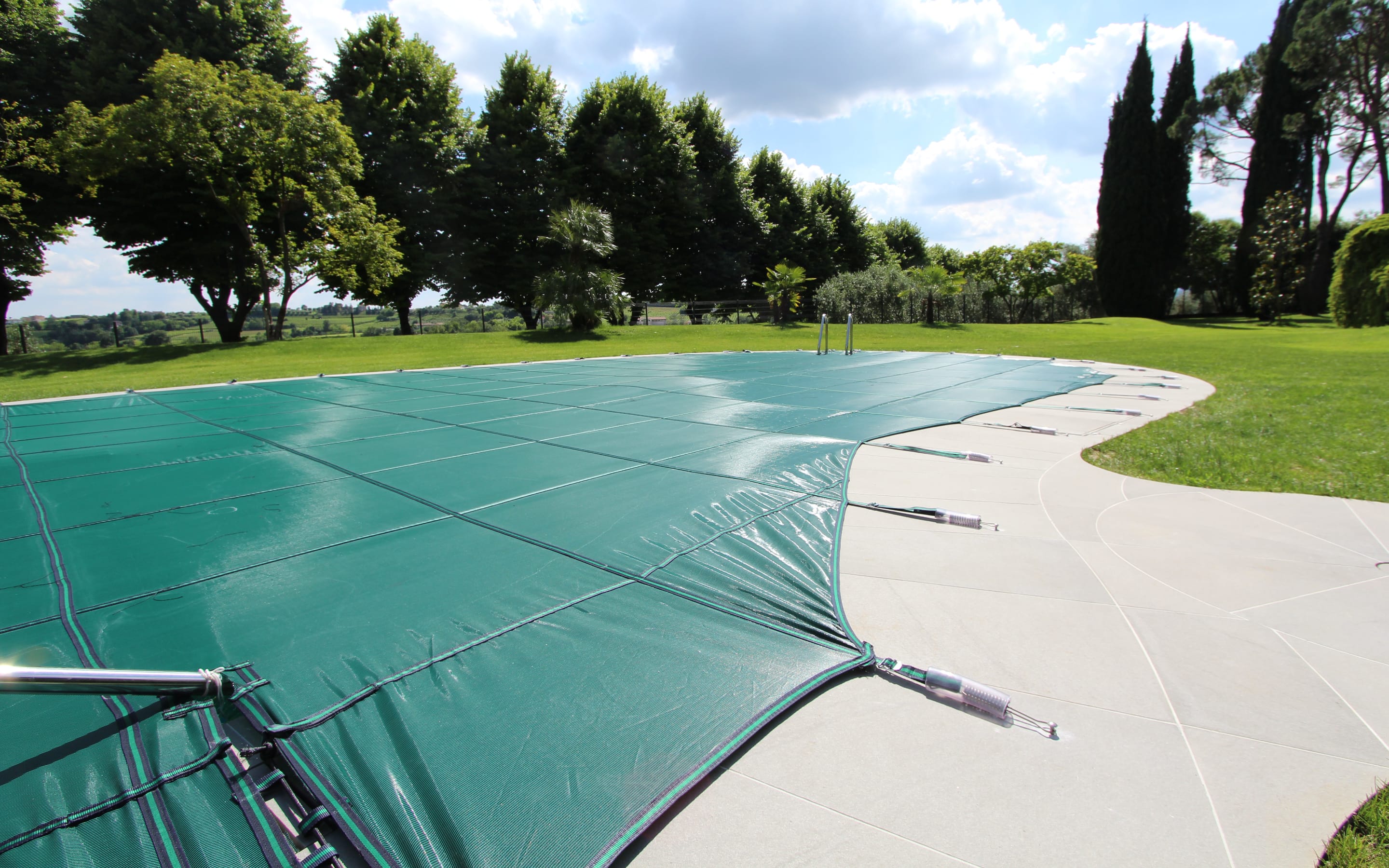

Tensile or tent structures are a valid ally in the industrial sector, as they allow us to create additional space to be used for good loading and unloading, storage, or processing of the material. In comparison to masonry works, they have many advantages and, depending on the needs of each company, they can come in different ways. Tensile structures, indeed, can be portable, fixed, or retractable.

In this essential guide to industrial tents, we’re going to describe the peculiarities, the advantages, and the different models of industrial tensile structures.

Tensile structures: meaning

Let’s start with the basics, i.e. the definition of “tensile structure”. The name itself says it well: they are realized with a load-bearing frame in hot galvanized steel and PVC covering membrane (single or double membrane to improve energy performance). As an alternative, they can have a sandwich panel cladding for excellent thermal and acoustic insulation, a good way to improve the habitability of the warehouse in all seasons.

The first tensile structures appeared at the end of the 19th century (the Russian engineer Vladimir Shukhov was among the first ones to design them) and became more and more popular after the Second World War. Nowadays they are very widespread not only in the industrial sector, but also in the field of trade shows, sports, and entertainment.

Advantages of industrial storage tents

The success of industrial tents has been determined by the real advantages they bring:

- easy to install: in comparison to traditional masonry works, tensile structures reduce building and installation time, thanks to shallow foundations and to fewer bureaucratic formalities;

- sparing: low mounting costs and shallow foundations result in effective sparing;

- flexibility: since there are no design constraints, tensile structures can be built according to the customer’s need, including free spans greater than 50 meters. Furthermore, unlike masonry works, this type of structures can be repositioned, i.e. they can be dismantled and reassembled in another production site;

- more space at your disposal: since they do not need internal columns, the working and storage space increases;

- energy efficiency: industrial tents have a natural brightness that lets you limit artificial lighting during the day, which results in energy saving.

Industrial retractable canopy

Industrial retractable canopies are a special type of industrial tensile structure. In this case, the structure can be folded to open or close the warehouse depending on your needs.

Fixed tensile structures and portable depots

If you need a tensile structure, you can choose among different variants. The first choice to make is between fixed and movable structures. In comparison to the first ones, moving (or portable) structures are more flexible, but you should not forget that both versions need permission to build.

Regulations for temporary and permanent tensile structures

As above said, then you decide to opt for a tensile structure, the bureaucratic procedures are easier. However, in Italy there are some regulations that you need to know and follow and which allow us to install 100% safe and efficient structures. A tensile structure, moreover, needs to be designed according to the technical building regulations (NTC2018) in relation to the geographical area where they are installed, respecting the snow, wind, and earthquake loads imposed. Before starting a project, we suggest that you ask a competent professional and the technical bureau of the city to get answers about permissions and regulations, which might change from place to place.

Favaretti Group offers various types of industrial tensile structures, all marked CE according compulsory EN 1090-1 and recalled in NTC 2018 E D.LGS 106/2017 in compliance with the UE N° 305/2011 regulation.